DIGITAL TECHNOLOGY

At cema we utilise industry standard software to engineer, calculate and design with accuracy and speed, but we are constantly looking for advancements that will improve the process.

To maintain our delivery focus, we must be flexible and steer away from the belief that one size fits all, so we review every process and every application constantly, improving links and developing new tools to bridge gaps and optomise interfaces. Finding the ultimate synergy for these applications and processes, produces measurably better results.

We believe the best solution is to keep it simple, only extrapolate the data that is required, anything more is just noise.

Below are some of the core applications we use daily, with bespoke software that links, enhances and automates production.

Design

PDMS – Plant Design Management System

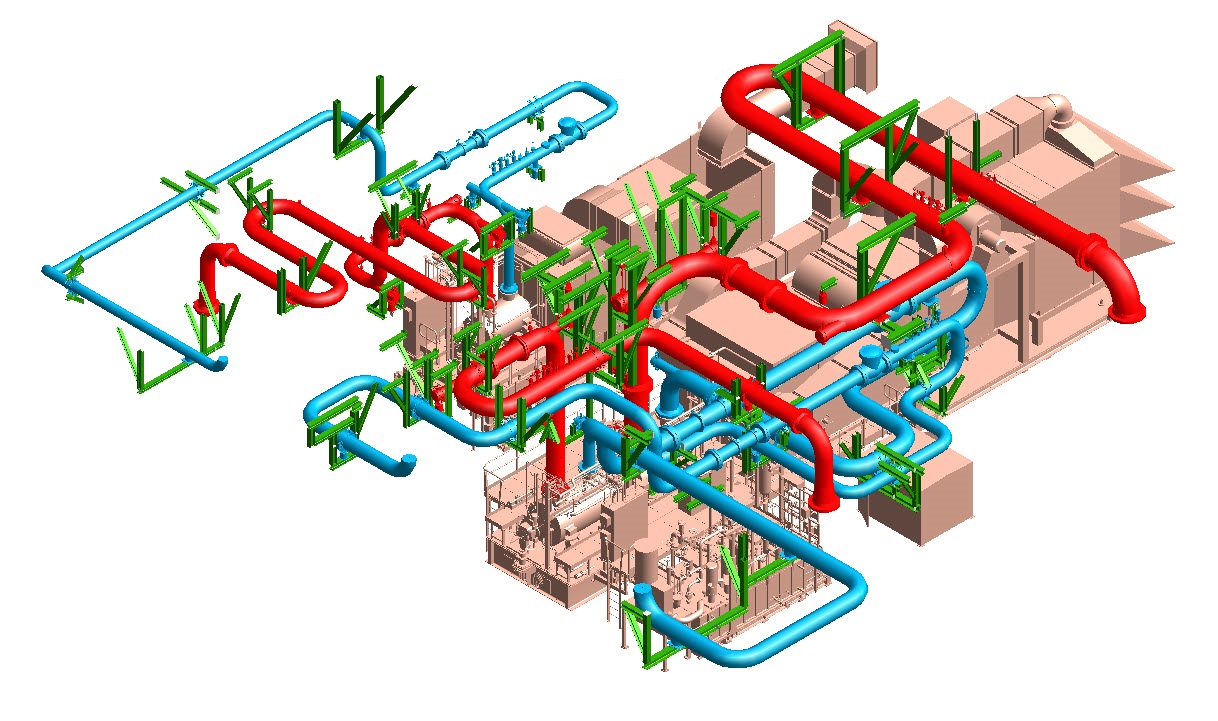

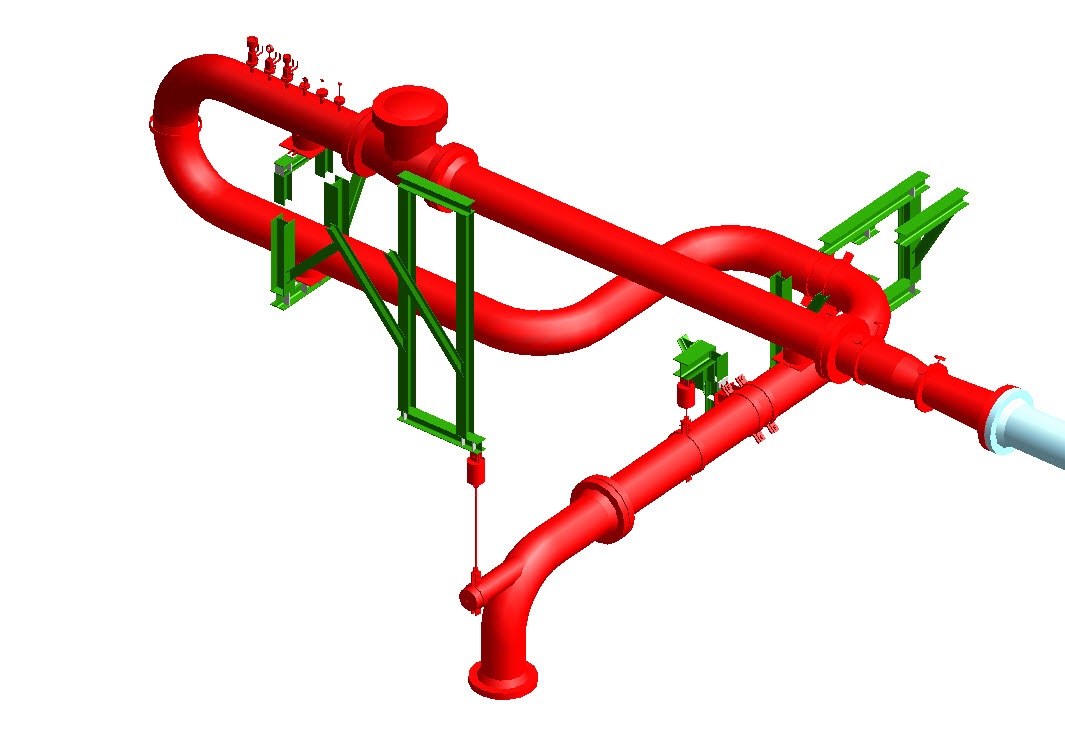

PDMS is customisable, multi-user and multi-discipline. It’s a controlled design software package for engineering, design and construction projects offshore and onshore.

PDMS makes it possible for designers to create structures, position pipe and layout equipment etc. while providing real time clash management awareness. It is a vital tool for constructability reviews during multi department review sessions.

With the creation of bespoke tools within the PDMS design environment, we are able to reduce modelling time, but the larger part of development has been within the deliverables production (draft) phase, which demonstrates the larger benefits.

Digital Twins

A digital twin is the generation or collection of digital data representing a physical object. The concept of digital twin has its roots in engineering and the creation of engineering drawings/graphics.

Digital Twins are the outcome of continuous improvement in the creation of product design and engineering activities. Product drawings and engineering specifications progressed from handmade drafting to computer aided drafting/computer aided design to model-based systems engineering.

Data from: Wikipedia

Digitalization

Point Cloud Survey

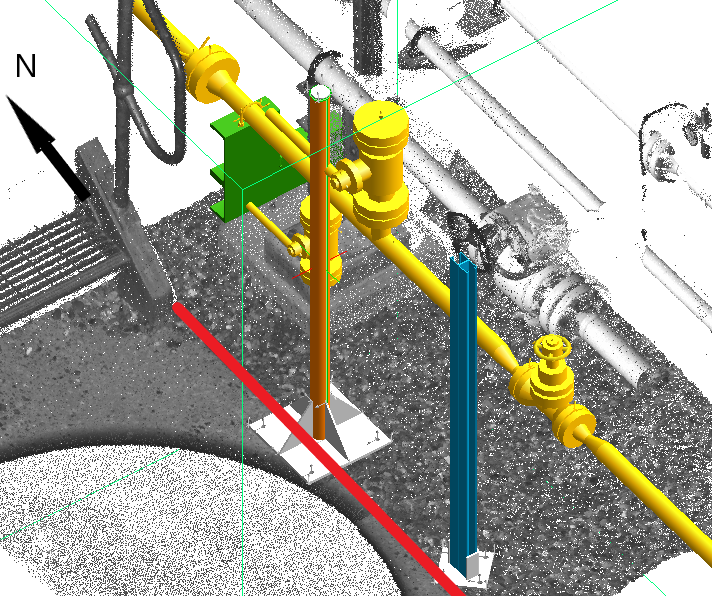

3D Laser Scanning is a non-contact, non-destructive technology that digitally captures the shape and dimensions of physical structures and objects using a line of sight laser light. Laser scanning uses a very rapid laser beam of up to 2 million points per second to scan the environment and capture a vast quantity of data from the surface of structures and objects in the form of a point cloud. Each point has it’s own XYZ coordinate and is referenced to a fixed datum.

In other words, a 3D laser scanning survey or a Cloud Burst Survey is a way to capture a structure or an objects exact size and shape and represent this in the computer world as a digital 3-dimensional model.

Image left is Point Cloud Survey and PDMS working together to create a clash free design.

Engineering

Staad Pro – Structural Analysis

STAAD.Pro is one of the most widely used structural analysis and design software products worldwide. It supports over 90 international steel, concrete, timber & aluminium design codes.

Caesar II – Pipe Stress Analysis

The industry standard for pipe stress analysis, letting you build, assess and report on piping systems of any size or complexity in accordance with more than 35 international piping code standards and many environmental and equipment guidelines.

If you have any questions or like further information, please get in touch

Secure Storage

All model data is securely stored on an air gapped system, ensuring zero external accessibility.

fast and secure distribution

All PDMS models are distributed on encrypted drives, these will normally be delivered to the owner for distribution to any third party as required. Upon completion the information can be verified and modifications incorporated into the stored copy.

The primary copy will always be secure.

PDMS UPDATES

As-building services are available on the PDMS model and 2D deliverables if required, ensuring that all your information is up to date and readily available.

___________________________________________________________________________________________________________________________________________________________________

Copyright © cema 2021